Hydraulic Pump Drives

HYDRAULIC PUMP DRIVES

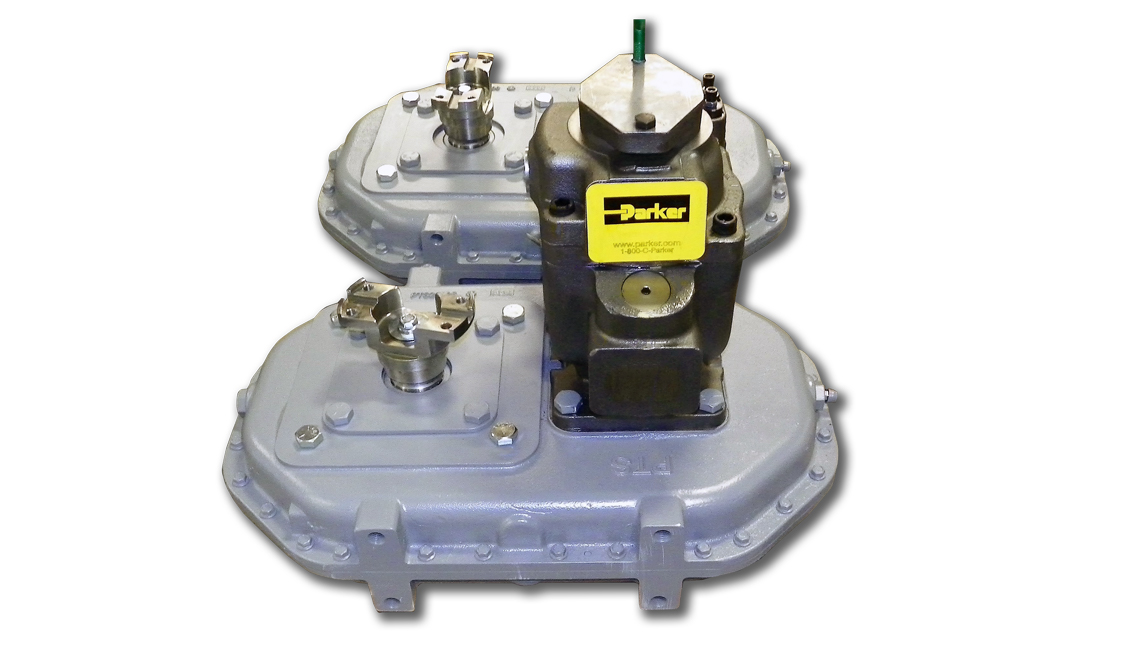

The hydraulic pump drive is a vital component for daily operations. Using the latest technology combined with over 30 years of experience in gearing and gearbox design, PTS delivers high quality, long life, low maintenance pump drives that keep our customers working.

FEATURES

- Pump centers (6″-8″-10.5″)

- Engine & clutch housings (SAE 1-2-3)

- Clutches (SP111-SP211-SP114-SP214)

- Drive plates (10-11.5-14-18)

- Shaft inputs (keyed, splined, flanged)

- Ratios (over 50% more than competitors)

- SAE pump pads (A-F)

- Types of inputs (shaft, plate, clutch, torsional)

- Fully sealed (O-Ring between housings, no thru holes)

- All fittings SAE O-Ring Boss

- Improved gearbox lubrication options

- Dual Speed

PARTNER WITH PTS

Power Transfer Solutions builds some of the most durable and efficient hydraulic pump drives in the industry. All hydraulic pump drives are manufactured to AGMA and SAE standards, with AGMA Class 10 gearing for longer life, less noise, and lower temperature rise.

Our drives feature a fully sealed gearbox eliminating common oil leak paths. All ports are SAE o-ring boss, eliminating leak-prone pipe threads. O-ring sealed housing halves eliminate gasket issues, and threaded fastener holes do not extend to the housing interior, eliminating leaking threads.

A variety of SAE standard input and output options are available.

Our dual speed option allows for pump drive outputs to be driven at different output ratios. For example, this means that your two pad pump drive can drive one pump at 1:1 and the other pump at 1.38:1. Contact PTS engineering for assistance with specific ratio speeds.

Custom pump centers, input configurations, and output configurations are available for your specific needs. Contact PTS engineering for assistance.